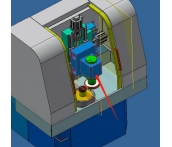

- SKMG73100 CNC Horizontal Grinding Machine

- Editor:xghlDate:2017-01-05 10:26 click:

- 產品詳情

- 產品參數

Equipment principle and structure:

SSKMG73100 uses the grinding head in the carriage for reciprocating carriage in the column rails for vertical movement of the form. Imported electrical equipment, rail with Rexroth, uses the latest design table to improve equipment stability and accuracy. Bed, pillars and other castings all use good secondary tempering stress relief processing material with high strength to ensure the stability of the equipment.

Advantage:

Independent research and development grinder feed NC control system with easy parameter settings. Set the size, automatically detects the knife, automatic resolution, automatic grinding, automatic compensation, automatic grinding. The workbench is equipped with automatic charge and a demagnetization device, with adjustable magnets to protect loss of magnets and functions. Strong casting rigidity, speed, high precision, easy operation and high efficiency production.

Application:

This machine is suitable for round surface grinding, the main grinding wheel diameter φ1000 within the scope of the circular end for processing flat pieces (Can be customized according to need)

Industrial Application:

Can be applied in workshop and tool workshop of the saw blade factory, the automobile factory, the bearing factory, the engine factory, the tool factory, the friction plate factory, the piston factory, the ceramic seal factory and the general machinery factory, the grinding precision parts;

Characteristics:

1. Adaptable to processed products.

2. High precision.

3. After processing up to Ra 0.4 μm, the thickness of the worlpiece gap remains 0.003mm within the surface.

4. The oroughness perator has low labor intensity, one person can control multiple machines and this reduces labor costs;

5. High production efficiency and good economic efficiency.

6. Simple grinder maintenance

7. Easy modernization for production management.

SSKMG73100 uses the grinding head in the carriage for reciprocating carriage in the column rails for vertical movement of the form. Imported electrical equipment, rail with Rexroth, uses the latest design table to improve equipment stability and accuracy. Bed, pillars and other castings all use good secondary tempering stress relief processing material with high strength to ensure the stability of the equipment.

Advantage:

Independent research and development grinder feed NC control system with easy parameter settings. Set the size, automatically detects the knife, automatic resolution, automatic grinding, automatic compensation, automatic grinding. The workbench is equipped with automatic charge and a demagnetization device, with adjustable magnets to protect loss of magnets and functions. Strong casting rigidity, speed, high precision, easy operation and high efficiency production.

Application:

This machine is suitable for round surface grinding, the main grinding wheel diameter φ1000 within the scope of the circular end for processing flat pieces (Can be customized according to need)

Industrial Application:

Can be applied in workshop and tool workshop of the saw blade factory, the automobile factory, the bearing factory, the engine factory, the tool factory, the friction plate factory, the piston factory, the ceramic seal factory and the general machinery factory, the grinding precision parts;

Characteristics:

1. Adaptable to processed products.

2. High precision.

3. After processing up to Ra 0.4 μm, the thickness of the worlpiece gap remains 0.003mm within the surface.

4. The oroughness perator has low labor intensity, one person can control multiple machines and this reduces labor costs;

5. High production efficiency and good economic efficiency.

6. Simple grinder maintenance

7. Easy modernization for production management.

- next: end...

- pre: SMG7350- horizontal axis rotary table surface grinding machi