- SKM7340—Horizontal Surface Grinding Machine with Horizontal

- Editor:xghlDate:2017-01-05 08:52 click:

- 產品詳情

- 產品參數

Round table surface grinder has two structural forms, one is a vertical rotary table surface grinder, one is horizontal rotary table surface grinder. Vertical lines of vertical circular grinder grinding, circular magnetic table, using the surface of the workpiece face grinding wheel, high processing efficiency. Round table surface grinder is suitable for generators, tools, bearings, magnetic materials, refractory materials, molds, die blanks, machinery and other industries where the need for surface grinding. Horizontal lines of horizontal rotary table surface grinder grinding, using a grinding wheel perimeter of the workpiece grinding, high precision machining. Ring for grinding parts, valves, blade, cutter and other tools, and precision parts machining, are widely used tools, bearings, saw, air compressor plant and other machinery manufacturing companies grinding precision parts .

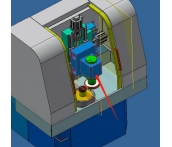

SKM7340 horizontal axis rotary table surface grinder is my company absorb advanced grinding machine structure and manufacturing technology to develop a new series of horizontal-axis rotary table surface grinder. Working round table diameter ф400mm, using the table in the bed rotation frequency, the carriage moves back and forth along a horizontal, vertical grinding head carriage moves along the feed layout patterns. Grinding spindle bearings with precision bearings, good rigidity, high accuracy.

Bed, column layout on linear guides and ball drive unit, using precision positioning servo motor. Stable overall structure is compact, high accuracy, reliable performance, good manufacturing processes, and easy to operate.

Using peripheral grinding wheel, the workpiece can get up and down the two planes parallel precision, dimensional accuracy and surface roughness. This machine is suitable for grinding circular parts, valves for precision machining, saw blades, cutters and other tools, tool.

SKM7340 horizontal axis rotary table surface grinders, bed, column, pallet, etc. all use resin sand casting foundry, good material, high strength. Grinding using bearing structure, contact rigidity, high precision movement, vibration absorption and stability than conventional bearing structure. Important parts of the machine, such as spindle bearings, ball and rolling element deputy, electrical components and other purchased parts, are used name brand manufacturers products, reliable quality, easy to maintain.

1, SKM7340 horizontal axis CNC rotary table surface grinder grinding reciprocate use in the column, as in the form of linear motion of the carriage on the rail bed.

2, grinding rigid bearing (hydraulic) structure spindle design, 5.5 (7.5) KW motor, maximum speed 1450rpm. Wheel Model (Ф350 × 40 × Ф127mm).

3, electromagnetic table, diameter Φ400mm, table with centering bearing positioning, rotating in a fixed position, using the plane bearing rotation. By the motor through the gear box, Ribbed, Ribbed wheel drive, motor power 2.2KW4 level. Table speed 40-460R / MIN adjustable.

4, cross feed and vertical feed device, by a servo motor (≥10N.m), gear box, ball screws, linear guides. In which the vertical axis has a brake or self-locking device, and with a grating absolute coordinate positioning.

5, grinders are set at each rail lubrication points are lubricated by an electric lubrication pump. For the table with a separate supply tank, into the back line through the towline rational distribution.

6, magnetic chuck using copper coil design, the surface faceplate design using concentric circles and cut flowers, customers can also customize the faceplate. Surface magnetic uniform and equipped with an automatic charge demagnetization device with a magnetic adjustable-loss protection and other functions.

7, the cooling water tank with 100L magnetic separator, cooling circuit via the towline of cool location. Magnetic separation motor power 0.12KW, coolant pump motor power 0.25KW.

8, using an independent electrical cabinet, independent console, CNC system control, two-axis, automatic control, auto-complete cycle of grinding.